I became interested in the reverse trike motorcycle concept by accident. I was browsing on the web one day looking for information on the Bugatti Veron after seeing one at a car show. I found a link showing a Veron and a T Rex racing. I was blown away by the concept of a sporty, two seat vehicle that had both the experience of being out in the elements like a motorcycle, as well as the comforts of sitting and driving like a car.

For the next few weeks I searched for more information on the T Rex and discovered it was a fairly simple tubular frame, three automotive wheels, and pretty much all the parts of a Kawasaki Ninja ZX-14R motorcycle – engine, transmission, engine and instrument cluster, electronics, etc.

I also discovered a number of knock-off designs that either had elements of style or motorcycle parts that made them different. Some of the knock-offs definitely were improvements on terms of style, but nothing really dramatic – put them all next to each other and you would think they were basically the same vehicle, just different models. One thing the T Rex and all the knock-offs had in common was the price – extremely high in my opinion for all the more this vehicle was.

I had been itching to start a new project for quite some time since Blonde Streak had been destroyed and I had tossed around the idea of building or restoring an automobile or something along those lines. I had build an airplane from scratch so why not a car? Now the idea of building a T Rex jumped to the top of the project list! Problem was the T Rex isn’t something you build – it’s pre-built by Campagna Motors out of Canada. Most of the knock-offs were kits so that was better, but still way too expensive. So I started looking into the possibility of designing and building one of these myself.

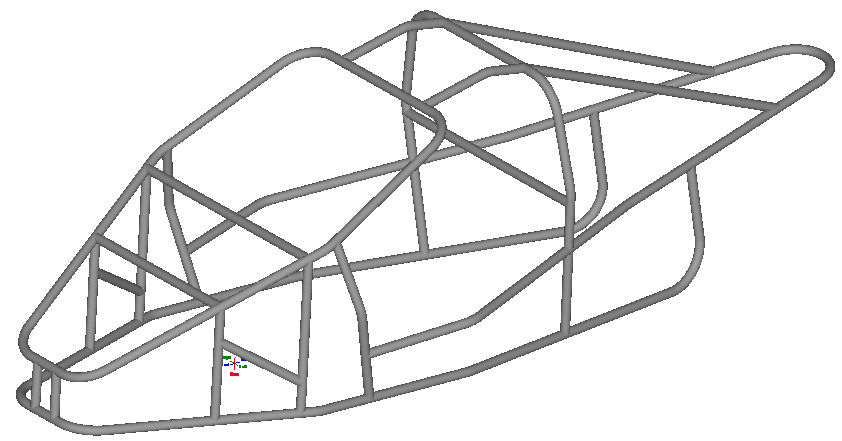

Like all projects, I did a lot of research into design and fabrication tools, parts, manufacturing methods, and similar projects others were doing around the world. I bought a design tool many people seemed to recommend for designing and constructing tubular chassis or roll cages called BendTech. After numerous layouts and design studies on paper, I started to use BendTech to lay out the preliminary design. Its a great tool and has saved me the effort in both design and fabrication. Below is a snapshot of the basic frame from BendTech.